As Much of Your Hose as Close to Your Cut-Off Saw as Possible.

High-Density Hydraulic Hose Storage Systems for Faster, Safer Workshops

At BAC Systems, this single principle guides our complete outlook on Hose Maniufacturing Workshop Storage:

store the maximum uncut hydraulic hose as close as possible to the cut-off saw.

By reducing the distance between hose storage and hose cutting, hydraulic workshops gain measurable improvements in efficiency, throughput, safety, and floor space utilisation. For many customers, simply rethinking hose storage layout results in faster hose assembly and less reliance on forklifts or manual handling.

High-Density Hydraulic Hose Storage—Without Compromising Access

BAC Systems designs and manufactures a unique range of modular hydraulic hose storage systems that compress large volumes of hose into a compact footprint—while keeping hose easy to access, easy to draw, and easy to rewind.

Whether your hose is supplied on reels, flat coils, or bundled large-bore lengths, BAC offers purpose-built storage solutions that integrate seamlessly into your hose-making workflow.

BAC Hose Reel Module

Ideal for small- to medium-diameter hose supplied on reels

The BAC Hose Reel Module is a free-standing unit with a footprint of just 1310 mm x 755 mm (4.3' x 2.5'), yet it stores 6 to 9 full reels of hydraulic hose, depending on spool size.

Key benefits:

-

High-density reel storage in a compact footprint

-

Conveyor roller design for smooth hose draw and rewind

-

Easy manual loading by two operators, or via forklift/crane

-

Empty spools removed quickly by hand

When positioned directly beside a cut-off saw, hose can be fed straight from the reel into the saw, eliminating unnecessary handling and wasted movement.

BAC Hose Drawer Module

Best suited for flat-coil hose (~15 m / 50 ft lengths)

Each BAC Hose Drawer Module includes seven individual hose drawers, with each drawer fitted with a rotating hose table that allows the hose to unwind smoothly.

How it works:

-

Place the flat hose coil onto the turntable

-

Cut the retaining straps

-

The drawer is immediately ready for use

Located near the cut-off saw, hose feeds easily into the saw and rewinds just as simply after cutting—keeping the workshop clean, organized, and efficient.

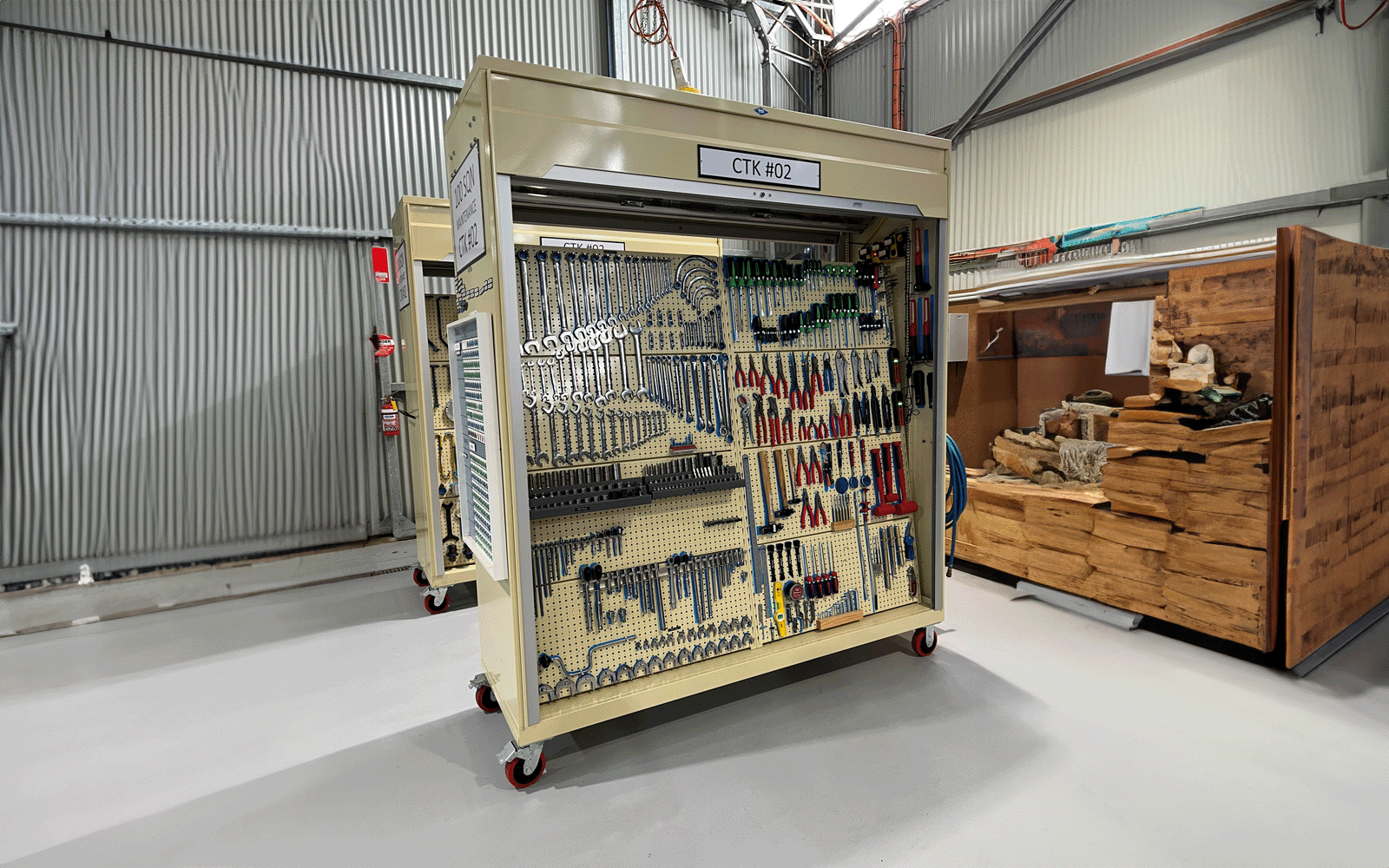

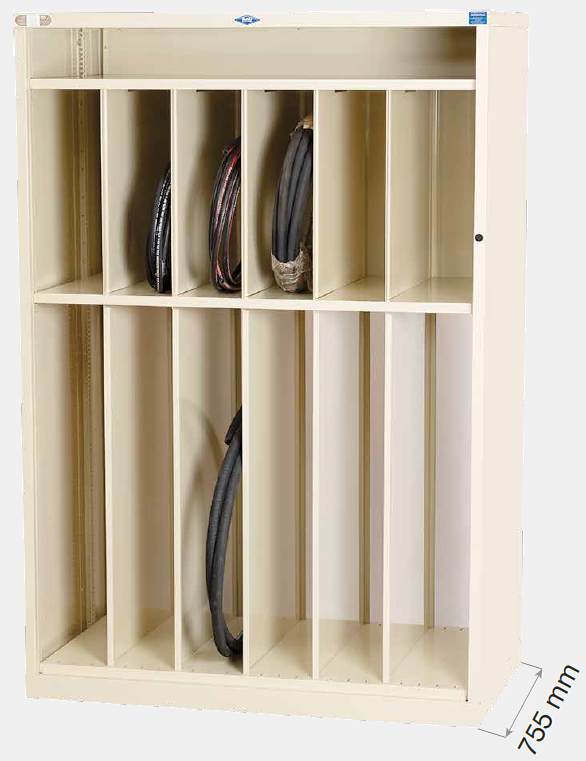

BAC Hose Shelving for Large-Bore Hose

Designed for bundled large NB hydraulic hose

Large-bore hoses supplied in bundles are stored with maximum density in BAC Hose Shelving Modules. Bundles are stood on edge and placed into vertical slots, allowing excellent visibility and space efficiency.

For cutting:

-

Bundles are transferred to a BAC Mobile Hose Unwind Bench and are transported to the saw

-

Only the required hose length is uncoiled into the saw

-

The bundle is retied and wheeled back to storage

This approach minimizes floor clutter, improves handling safety, and maintains order in high-volume hose workshops.

Why High-Density Hose Storage Matters

By adopting BAC Systems’ modular hose storage solutions, workshops consistently achieve:

-

Reduced floor space requirements

-

Faster hose cutting and assembly

-

Less forklift use and manual handling

-

Improved safety and organization

-

Hose stored closer to the point of use

When combined with a BAC Hose Making Workbench—featuring hose measuring channels, saw tables, and thousands of fittings stored below—hose setup times can be reduced dramatically.

Complete Hose Workshop Solutions

BAC Systems offers pre-configured Hose Workshop Bundles to simplify the design and setup of new hydraulic hose-making facilities, as well as upgrades to existing workshops.

Contact BAC Systems

United States

Jim Burns (Northwest Industrial Supply Inc) - jburns@nwisupply.com (+1 406-671-9899)

Australia

Bob Griffin (BAC Systems Pty Limited) - bacsales@bacsystems.com.au - (+614 07 488 634)