The Best Way to Store Small Parts in a Warehouse

Q. What is the best way to store small parts in a warehouse?

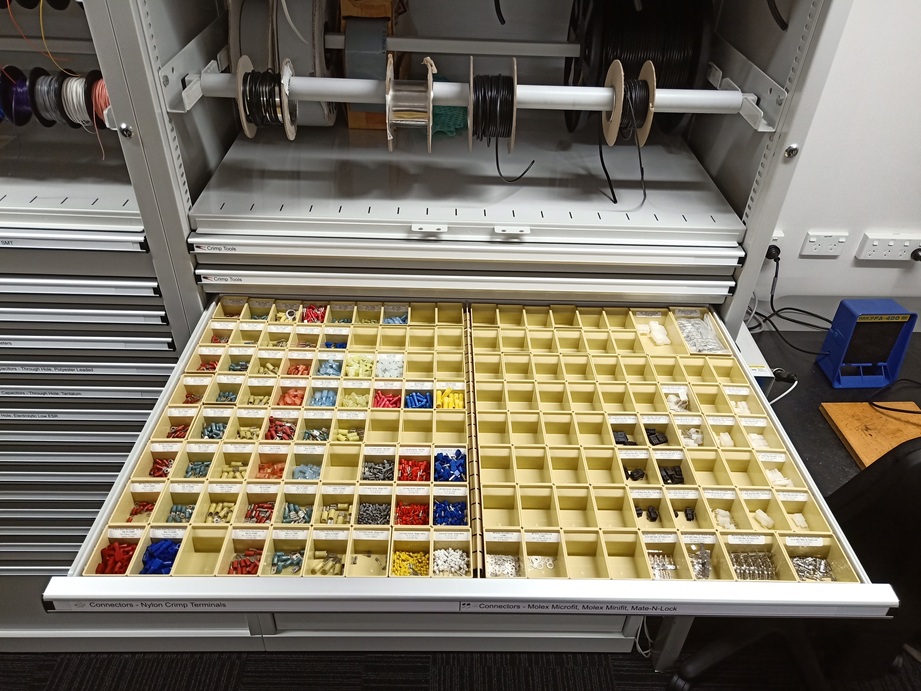

A. The best way to store spare parts in a warehouse is in High Density Drawers

BAC High Density Drawers have continually proven to be the best solution for small parts storage in a warehouse. They have all the features you would expect: Strong, extremely long-life, easy to adjust when your inventory changes – in addition to these, anecdotal evidence has shown us that it is an extremely fast way to pick parts. Coupled with this, BAC rightfully have the reputation for one of the best solutions for ensuring that your inventory uses the smallest footprint possible.

The key to the speed of picking parts from drawers lies in two aspects: the decreased footprint used and the systematic layout of the cabinets.

The science to the speed benefits offered by a compressed footprint is very simple – if you don’t have to walk as far, it does not take as long. BAC can reduce your storage footprint down to about a third of that footprint required by shelving to store the same items. In the process of this compression, the deeper BAC Drawer cabinets also manager to reduce the number of aisleways, not only saving you space, but reducing the storage-face, and thus reducing the distances required to be travelled. If most of the time of the pick is walking there and back again, then reducing this time is obviously going to speed up the pick noticeably.

BAC Drawer Storage Cabinets are Modular. At BAC, we often refer to them as “Drawer Storage Modules.” This name denotes their flexible nature, and the fact that each cabinet is an element in a greater storage system, with its own internal elements, all of which can be configured to suit the inventory being stored, the available space, the warehousing methodology being used. This creates a very logical storage system with locations that can be easily recognised with 5 Dimensions: Row, Cabinet, Drawer, x (column), y (row). This logic makes part locating clean and simple with any inventory management system capable of 5 dimension locations. Furthermore, the system is intuitive for the picker, who looks at the location code, which begins with the first dimension (knowing which aisle to enter) and progresses down to the last dimension in quick and logical order.

Click here to view the full range of BAC Industrial Drawer Storage Cabinets

Not only does the modularity of the BAC Drawer Cabinets ensure fast picking, but it guarantees the ability to remove dead space and reduce your footprint. BAC Drawers have adjustable internal partitioning. As your inventory changes over the decades, you can quickly and readily adjust the internal drawer partitions to suit the location sizes needed. You eliminate the dead-space behind and above the parts, endemic to even the best shelving layouts, and you eliminate a large portion of the aisleways, putting more floorspace into use for storage, and less for walkways.

BAC Drawer Storage Cabinets are built stronger than the alternatives with the largest roller bearings and high-strength Australian steels used. Maintenance is rare and minimal, and there are no ongoing costs or power usage. Up to a ceiling of 4 metres, nothing can out-store a drawer cabinet (in our opinion), and beyond that, well, you have to make your own risk assessments, because there is security in always being able to access your parts at ground level in a reliable drawer storage cabinet, especially in a high-volume warehouse.

To learn more about how BAC Drawers can be the best solution for your warehoused small parts, request a complimentary site survey from your local BAC Technical Sale Representative, or you can click here to view the full range of BAC Drawer Storage Modules.