The Prudent Choice: High-Density Drawer Storage as a Superior Alternative to Shelving for Small Parts Warehousing

High-density drawer storage cabinets offer superior volumetric efficiency and access compared to traditional shelving for small and medium parts, often tripling storage capacity within the same footprint.

I. The Inefficiency of Conventional Shelving for Small Parts

Since the earliest days of commerce, the shelf—a simple horizontal plane—has been the primary means of elevating inventory from the floor. Whilst a time-honoured technique, its modern application in warehousing, particularly for small to medium-sized components, presents several profound inefficiencies.

Traditional shelving is demonstrably wasteful in both volume and cost, presenting specific challenges for astute warehouse managers:

- Volumetric Waste: Shelving typically wastes a substantial multiple of the volume it successfully utilises for storing small items.

- Dual Storage Systems: When employing tubs or boxes upon a shelf to impose order, the user is effectively procuring a shelf to merely support a secondary storage system. This unnecessarily compounds the total cost of the storage solution.

- Imperfect Container Match: Standard storage boxes and bins rarely correspond perfectly to the dimensions of the items they contain, resulting in considerable dead-space above the stored contents. Managers frequently maintain this void to allow visual identification of the parts.

- Structural and Access Deficiencies:

- The structural component of the shelf itself (typically 25mm to 30mm) consumes approximately 20-30% of the vertical storage volume when shelves are closely spaced for efficiency (e.g., above a 75mm-100mm high box).

- To inspect contents in closely packed locations, one must sequentially extract each individual container, sacrificing speed and efficiency for limited volumetric gain.

- Depth Constraints and Footprint: Shelves are often limited to depths of 300mm to 400mm, which necessitates a greater number of aisleways, increases the total count of navigation locations, and significantly extends the travel distances required for parts picking operations.

II. High-Density Drawer Storage Cabinets: The Superior Three-Dimensional Solution

The drawer cabinet—a cousin to the shelf—offers a compelling remedy to these limitations. The term 'drawer' is derived from its inherent function: allowing the user to draw (or pull out) the container.

The mechanism of the drawer inherently combines the functions of the shelf and the box that would typically sit upon it, immediately recovering the 25mm to 30mm of height wasted by the supporting shelf structure.

Key Advantages of Warehouse Drawers:

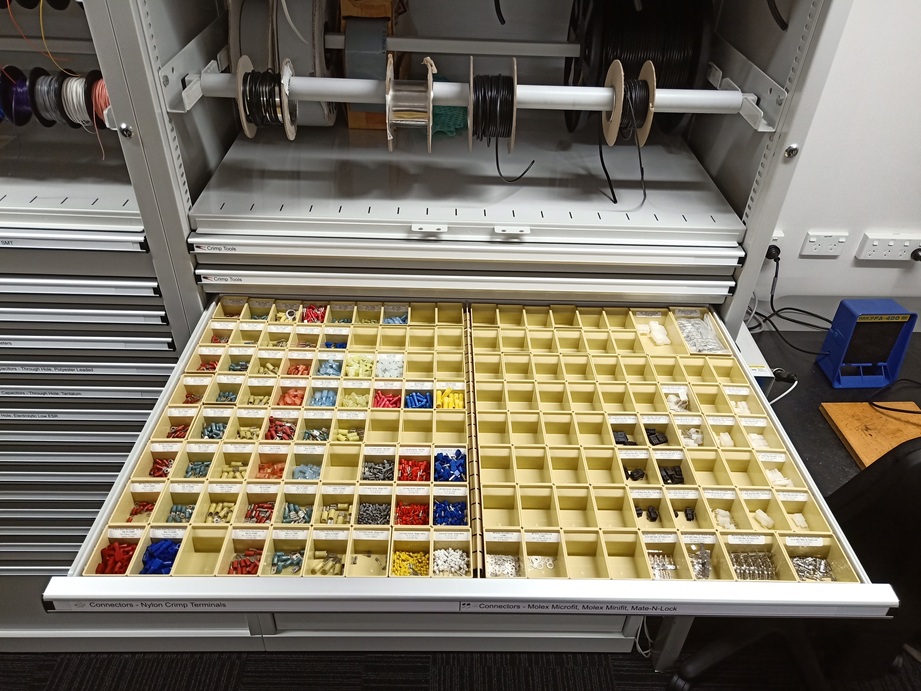

- True Three-Dimensional Configuration: High-density drawer systems allow precise configuration of height, width, and depth for each location, moving storage assessment beyond the single-dimensional measure of "linear metres of shelving" to actual volume.

- Unrivalled Accessibility and Vision: A whole drawer—which may contain between 12 and 72 distinct locations—can be extracted at once without risk of spillage. This instantly affords the picker a comprehensive, simultaneous view of every part and its corresponding label, a stark contrast to the singular box extraction required with conventional shelving.

- Maximised Vertical Volume: As a drawer is functionally a series of robust, joined containers, parts can fully occupy the maximum vertical height of the location. Unlike sloped bins or louvre-style containers, there is no open front that limits the utilisation of available cubic volume.

- Enhanced Depth and Reduced Travel: A quality drawer cabinet is designed to be significantly deeper (front-to-rear) than typical shelving. This pivotal characteristic reduces the necessary number of aisleways within the warehouse footprint. The resultant benefits are manifold:

- More parts stored per square metre of floor space.

- Fewer walking metres for picking personnel.

- Faster overall picking times.

- The ability to consolidate parts closer to critical processing locations.

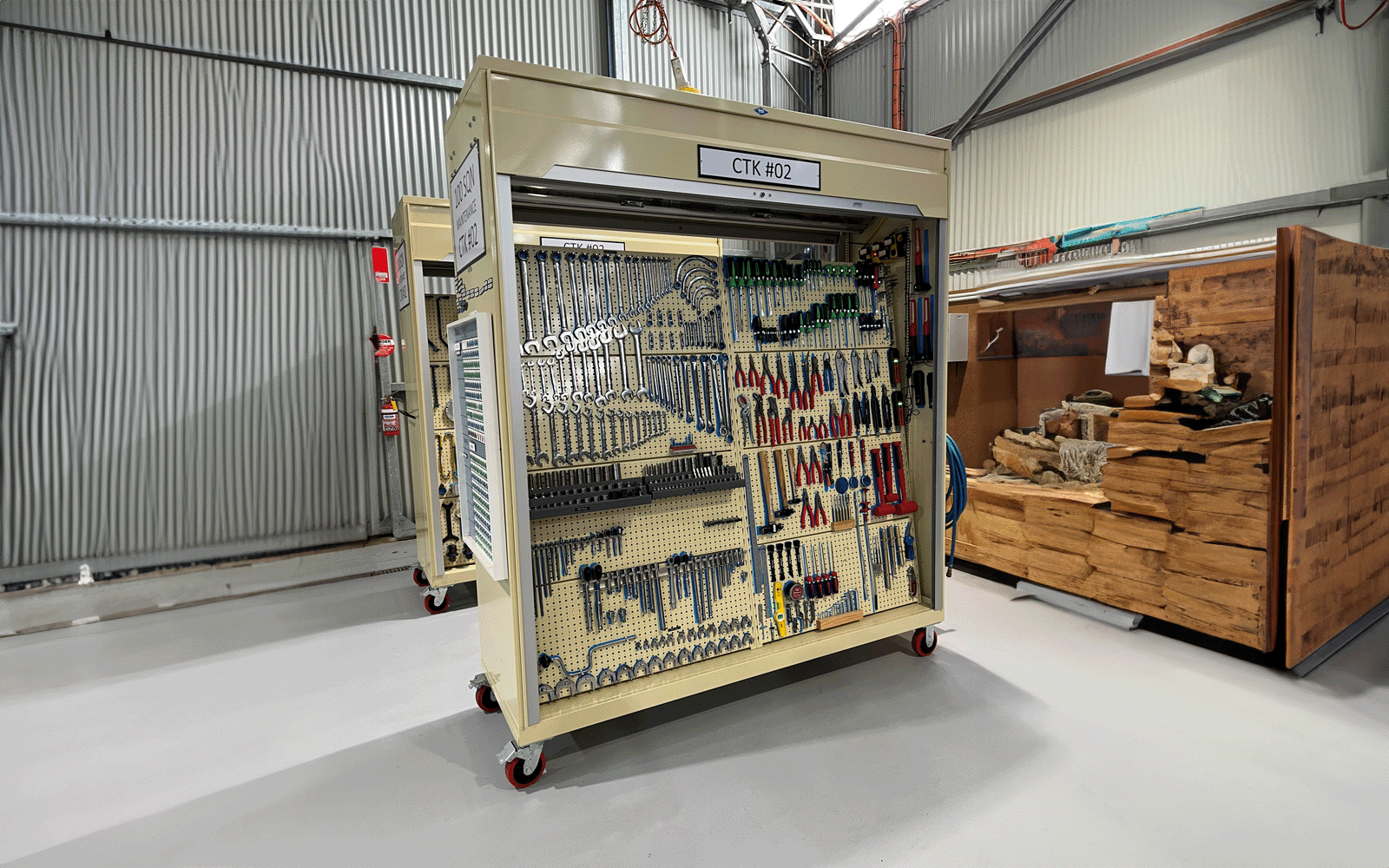

III. BAC Systems: The World Leader in High-Density Small Parts Storage

BAC Systems is internationally recognised as the premier choice for High-Density Drawer Storage Cabinets, providing robust solutions that are often engineered to outlast the facilities they occupy.

BAC storage solutions are distinguished by their commitment to quality and thoughtful design:

- Modular Design: Cabinets are designed for modularity, providing the three-dimensional flexibility required to eliminate the wasted space inherent in fixed shelving systems.

- Superior Construction: BAC utilises thicker steel gauges than many competitors, sourcing local Australian Steel manufactured to exacting specifications.

- Flawless Operation: Drawers are supported by high-tensile rails and substantial roller bearings, ensuring decades of perfect, reliable service. BAC cabinets frequently boast load-ratings that significantly exceed those of standard warehousing shelving.

- Expert Consultation: The BAC Systems team provides a valuable service network of technicians and consultants who collaborate with clients to optimise warehouse and parts store layouts. By combining the client's inventory knowledge with BAC's product expertise and anecdotal experience, the team ensures the delivery of the most functional and efficient storage configuration possible.

IV. Actioning Prudent Investment in Your Operations

The effective management of storage is a quiet, yet critical, element of any successful enterprise. Whilst some companies may negligently default to filling floor space with inefficient shelving, and others may imprudently invest in unproven automated systems, the prudent organisations recognise storage as a quantifiable factor impacting their return on investment.

These discerning businesses strategically balance their inventory needs, often combining high-density drawer storage for small-to-medium spares with necessary conventional shelving and pallet racking. This judicious approach yields significant, measurable advantages:

- Reduced floor space dedicated to storage, freeing volume for production or other core activities.

- Optimised sizing and deployment of the warehousing team.

- Minimised wastage throughout the parts operation.

If your organisation wishes to join this group of prudent businesses poised for operational success, you are invited to engage with BAC Systems. We offer a complimentary service wherein an experienced representative can survey your site or review your existing plans.

BAC Systems will subsequently devise a proposed storage configuration, provide verifiable data to substantiate its efficacy, and create three-dimensional drawings to aid in visualisation.

Please contact BAC Systems today to arrange this complimentary site survey and begin your journey toward greater warehousing efficiency.