Why you should buy a workbench from a workbench manufacturer

This may seem like a strange title for a post - it seems obvious, right? Perhaps, upon reflection, you might realise what it is referring to, though. You see, we come across so many people who use joinery instead of a workbench, or pallet rack shelves instead of a workbench. Occasionally, this might be appropriate, but an industrial workbench is so much more than a work surface supported by whatever is convenient.

Workbench manufacturers know this: we make a living from understanding what a workbench needs. Here are some key points:

- Structure. OK, so pallet rack frames are decent structure for a workbench, but joinery is problematic. Most often it lacks strength, and the material used is mostly some timber board variation which is susceptible to damage or rot. The joinery methods end up stretching over time and under load, resulting in swaying benchtops.

- Height and ergonomics. Whichever workbench option you choose, you have to consider height, the space available and the way you wish to work on it. A well designed workbench will have some semi-permanent means to set the height to where you want it to be, unless a fixed height can prove ergonomic and effective. Length and depth also have to be configurable to suit your enviroment and work method.

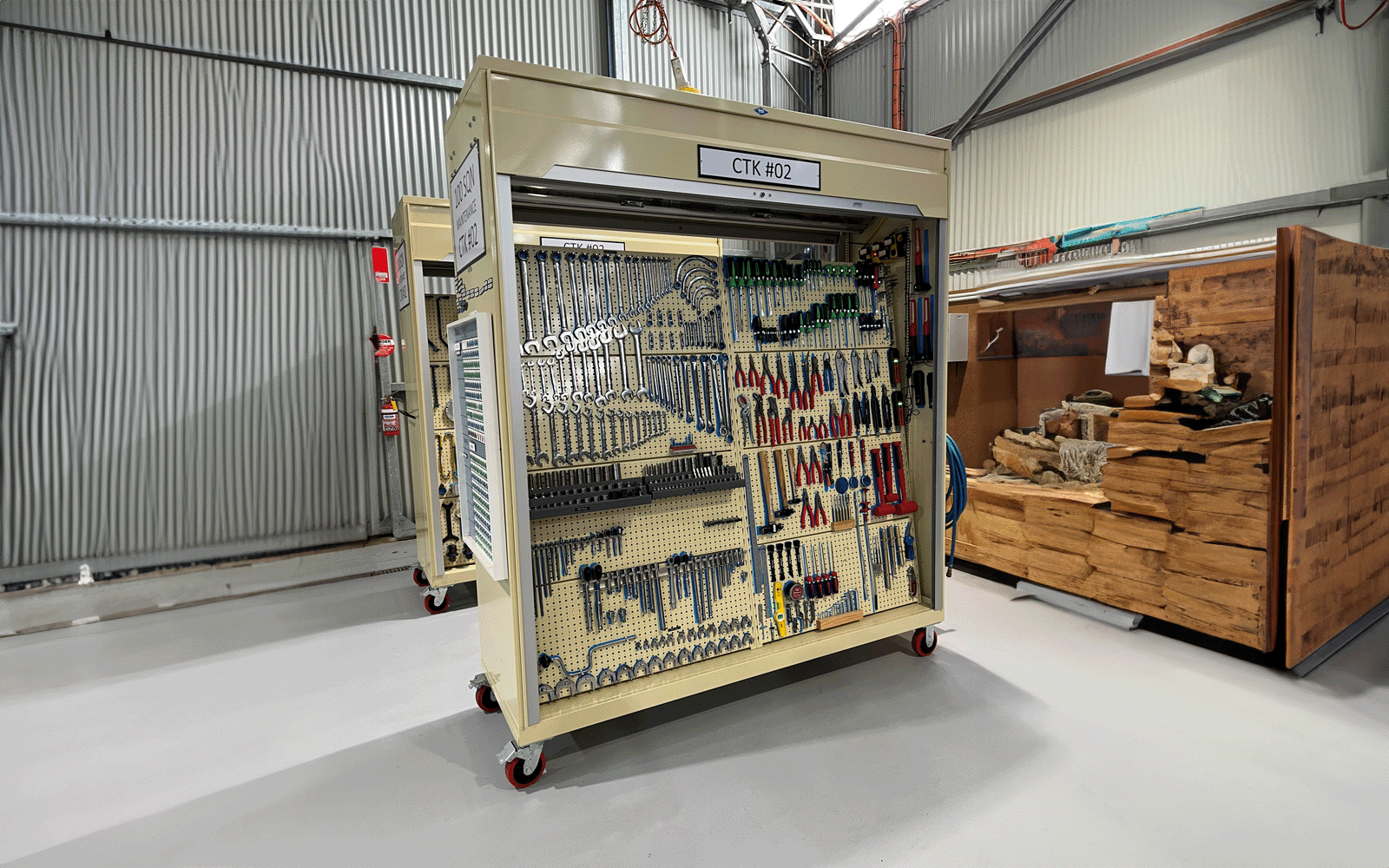

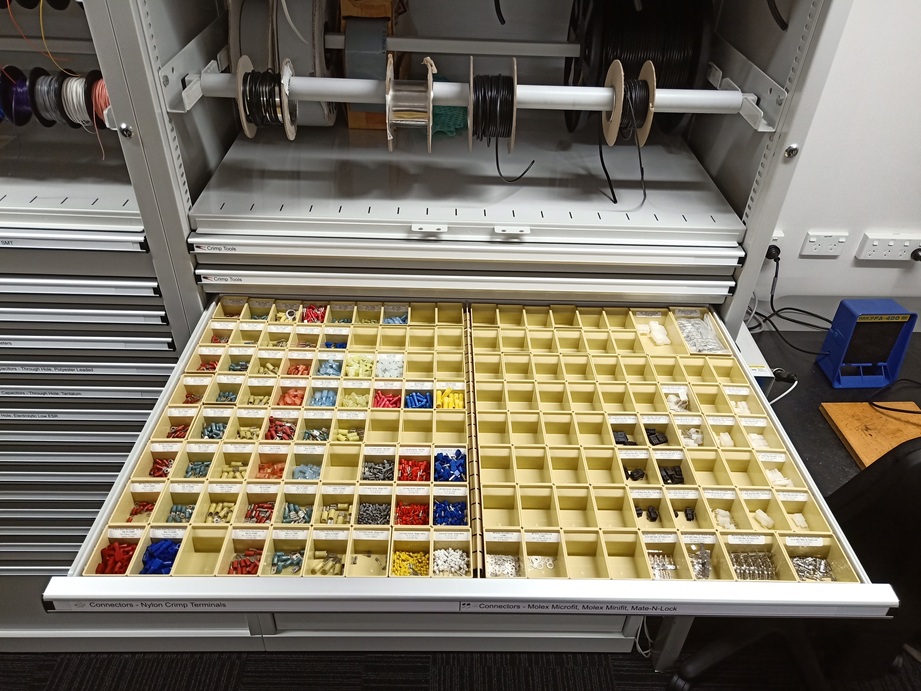

- Storage. A joinery cupboard with a couple of shelves, or an open shelf under the bench can work for a few scenarios, but not for most. In fact, they are rather lazy solutions, often sought by "decisions-makers" who won't be using the workbench. Technicians, fitters and general labourers will all know that tools and equipment without a dedicated location will be either lost, or cumbersome to access. A proper storage system is modular, and should be configurable for most scenarios. A dedicated workbench manfuacturer will have such a system as part of its range.

- Services. Whether is is a powerduct, lighting, ducting for air, embedded lubricant reels, or a host of other options, many industries require dedicated solutions for mounting their services within the confines of their workbench.

- Fit-for-purpose. Structures chopped up and held together by chipboard screws or tek screws just weaken over time with use. A workbench should last you half a century without swaying. All components must fit together, must be firm and rigid, must consider ergonomics and workflow, and must be strong. In a word, they must be modular. Every workplace is different, and unless you have a modular workbench system that can be reconfigured for each specific scenario, then you won't be able to provide a long-lasting solution.

BAC Systems is a dedicated modular Workbench manufacturer. Their range of industrial workbenches have decades of experience behind their design. Workbenches can be either fixed or mobile, can come with countless variations of embedded storage, can be fitted with a range of services and service ducting, are build from steel and other suitable materials, and are made fit-for-purpose.

At BAC Systems, when we sell you a workbench, we consider you space available, the equipment you wish to store, the options you wish to include, and the way in which you wish to work.

When you come to a workbench manufacturer, you will receive a solution, not just a kitchen bench or a shelving surface.

To learn more about the BAC Range of Australian made Workbenches, click on this link here, or contact the BAC Technical Sales Team on +612 9832 2777 in order to arrange a free site survey.