The Superiority of a Proper Spare Parts Drawer Solution

Q. Which is better for storing small spare parts - Drawers or Trays?

A. In most situations, a proper drawer storage solution with internal partitions far exceeds any benefits that Trays may offer, and hence is the best solution.

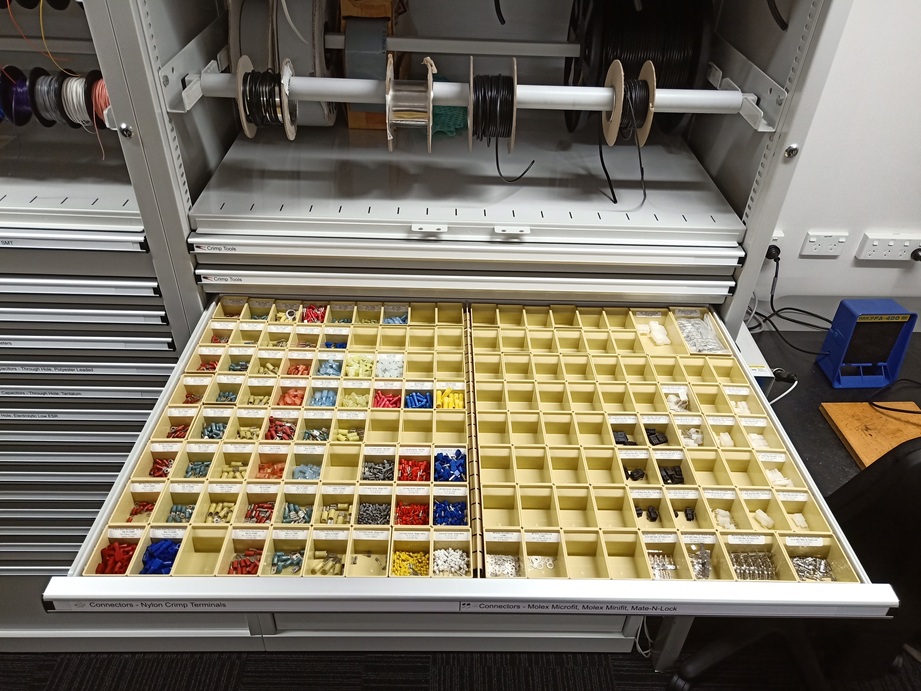

By proper, we mean that the drawer storage system in question must be a modular system, with adjustable internal partitions and dividers, and that this modular drawer storage cabinet must be properly set up with consideration for what is being stored so that your drawer locations reflect the size and quantity of the spare parts.

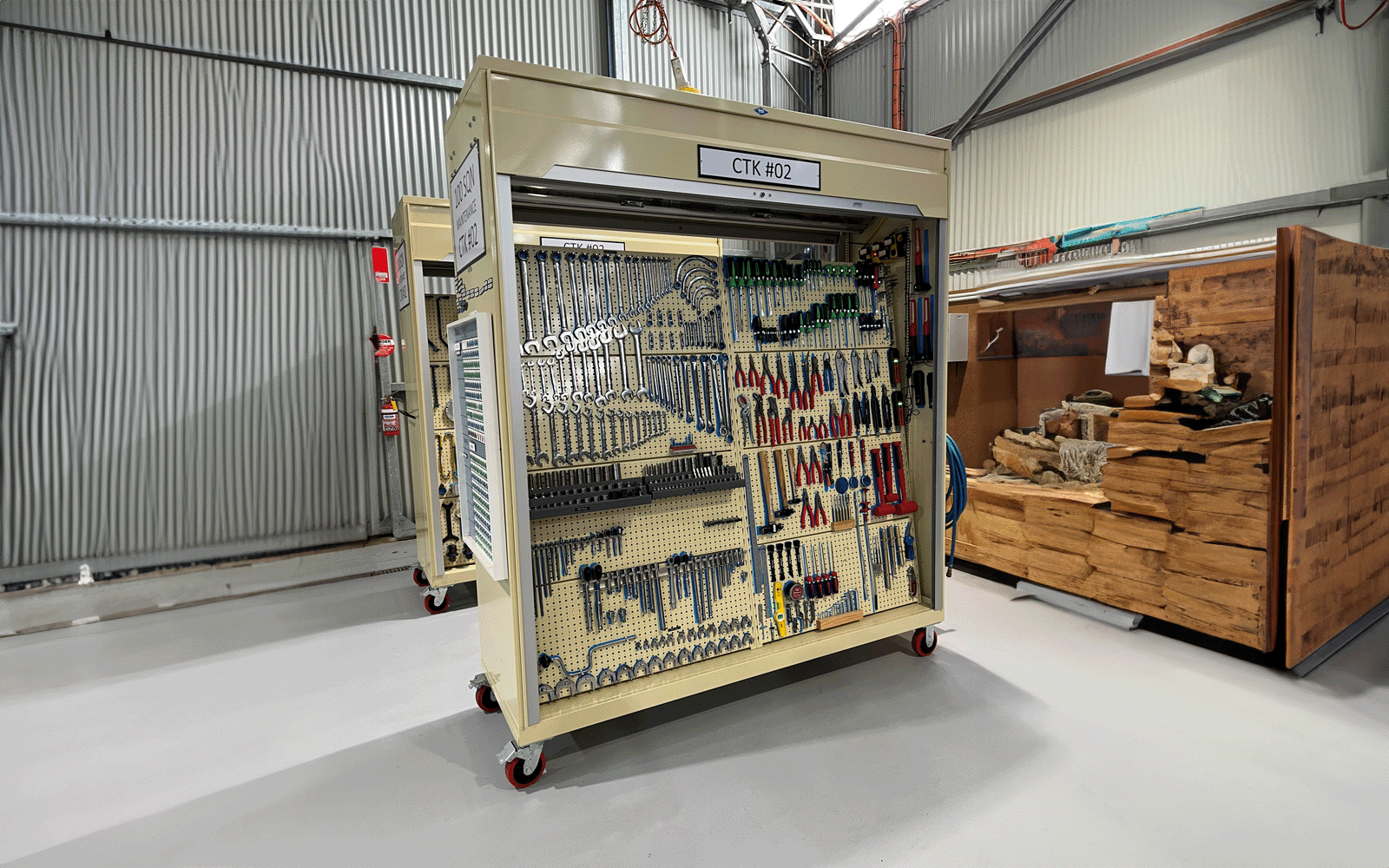

At BAC Systems, manufacturers of arguably Australia's most "proper" modular Drawer Storage Cabinets, we make it simple to "properly" set up your drawers. Our drawer heights and location sizes can be selected before you purchase your cabinets and then can be easily adjusted later on as your inventory changes over the decades. The BAC Technical Sales Team will even help you choose your location sizes, coming to your site and surveying your inventory and the way you operate. This is proper - the way parts storage should be set up.

The result is that a BAC Drawer Storage Module wastes very little space.

When compared to Trays, people often state that trays are easier to access, that parts are more visible, and that they don't require as deep an aislway as drawers require. We believe that people who make these claims haven't tried using drawers, because most drawer users would laugh at the claims, and swear by drawers. Let's try to go through these three points to get to see why:

- Are Drawers harder to access? No. In fact, drawers roll out smoothly, even under great load, and give you instant and easy access to a large volume of parts immediately. Drawers are all below eye-level, whereas many parts trays are sitting on shelves up high in an attempt to be as space efficient as drawers, and when they are full of parts, this might be harder to access. Drawers support themselves. Trays on shelves need you to support them to access them. In fact, most trays on shelves nowadays are like small, inefficient drawers without smooth bearings or the safety of stops.

Louvre bins might be easier to access, if you have them all spread out so that you can fit your hands between them, but the cost of that easier access is a massive waste of space and a lot more walking around for the same volume of parts. - Are parts in drawers less visible? That depends if you are talking about when you are taking a look at your parts from 10 metres away, or, if you are actually trying to pick a part. Of course, from 10 metres away, drawers are closed and parts are invisible. When you aren't picking parts, that makes the place look tidy, and that is what you would prefer. When you are picking parts, when visibility counts, most trays on shelves are no better than drawers, unless you leave 200mm clear height above the parts tray before the next shelf supporting the next tray, and that would be a stupid waste of space (and add more picking time as your parts would be spread out further).

In a warehouse with drawers, you will either be picking based off a location number given by an inventory management system, in which case, visibility is irrelevant, or, you would have a small storage system, either a few rows of shelves with boxes, or perhaps two drawer cabinets, in which case you would have roughly memorised the locations of parts and you will know where to go, so, visibility is probably not relevant.

Still, if you want visibility, pulling open a drawer, an act that takes only a second, gives you better visibility of between 10-70 parts instantly, than walking past shelves peaking at the gaps above trays.

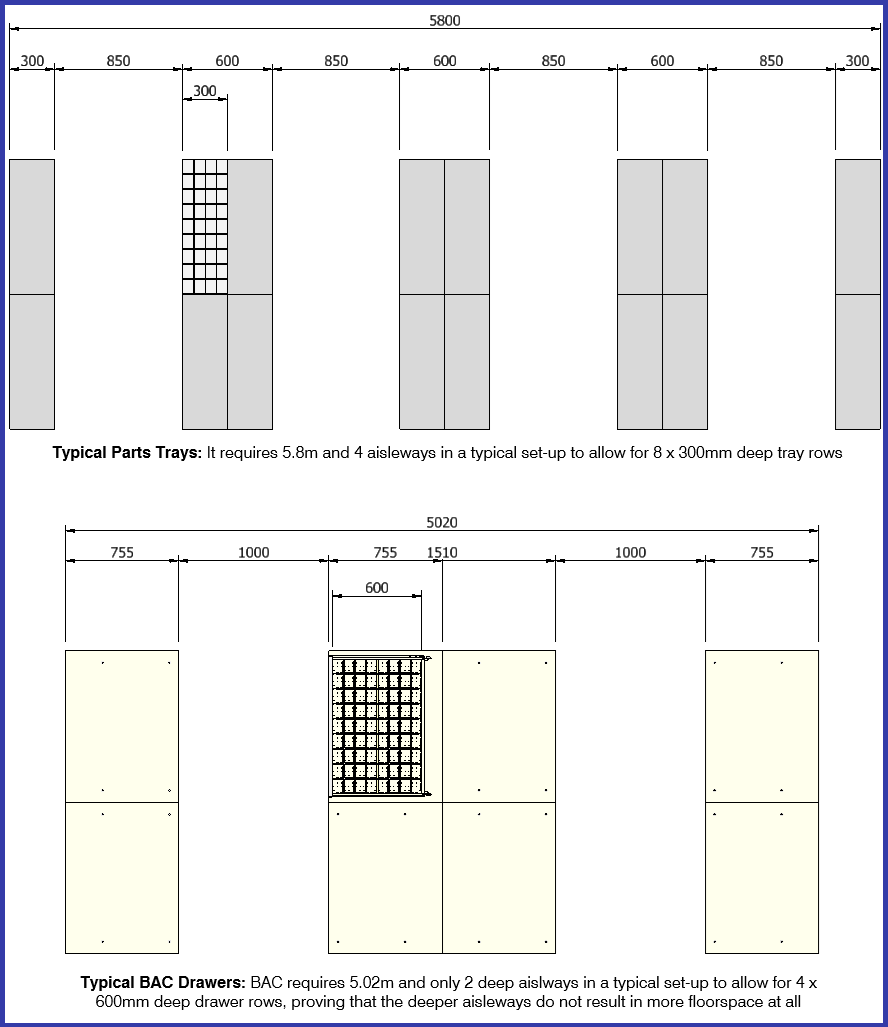

Once again, if you choose to store parts in louvre bins, you could get better visibility, but, once again, the cost in space and walking distance is massive. In fact, Louvre bins should really only be considered over drawers if you only have 10-20 small parts to store in total. - Do drawers require deeper aislways? Of course. A proper modular drawer storage system has a deep drawer and you need room to allow this drawer to be drawn out, and room for you to stand behind it. At BAC Systems, we recommend an average aisleway of 1 metre.

But...

Consider that trays on shelves, being 300mm deep best case, only fit 300mm of parts on them, and require an aisleway of about 850mm minimum (give or take). The trouble is that shelves need more aisles to store the same depth of parts. For example, if you have four aisleways with trays on shelves on both sizes, it will take up 5800mm. In the worst case scenario, a BAC Drawer Storage System, would only require 2 aislways of opposing drawer cabinets to store the exact same footprint - and this only requires 5020mm! This shows, that the deeper aislways are more than offset by the fact that the deeper storage units result in fewer aisleways