BAC Systems increases your production with Point-of-Use High Density Storage

In these times of mega-factories, massive mines and fine-tuned logistics, never before has there been such a keen need for fit-for-purpose parts and consumable storage.

BAC Systems Storage Module Drawer with Plastic Dividers

In these times of mega-factories, massive mines and fine-tuned logistics, never before has there been such a keen need for fit-for-purpose parts and consumable storage. Trying to put enough of the inventory right where it needs to be used is a key part of achieving this. BAC Systems has built-up its product range around solutions to solve just this issue and has taken the time to consider some of the problems that need to be overcome before any storage system can truly be considered fit-for-purpose.

Walking. The first and, perhaps, the greatest of all unnecesary time usages in the work-place is walking. The last thing needed is for a worker to walk a half-hour round trip merely to get a new light-bulb, or an R-Clip. Along the way, they may stop to have a quick conversation with one or two people, thus interrupting their work as well. Obviously, the analogy could be turned into a time-wasting horror story of other likely ways that time could be wasted long the course of getting this tiny part.

Coupled with the time wasted in getting the part is the risk of misidentifying the part. Over-burdened parts stores and consumables stores often resort to putting multiple items in a single location, in like order. How easy is it to grab the wrong screw, flat washer, fuse, or bearing, in this fashion? What is the end result? An additional long walking trip for the correct part, at best.

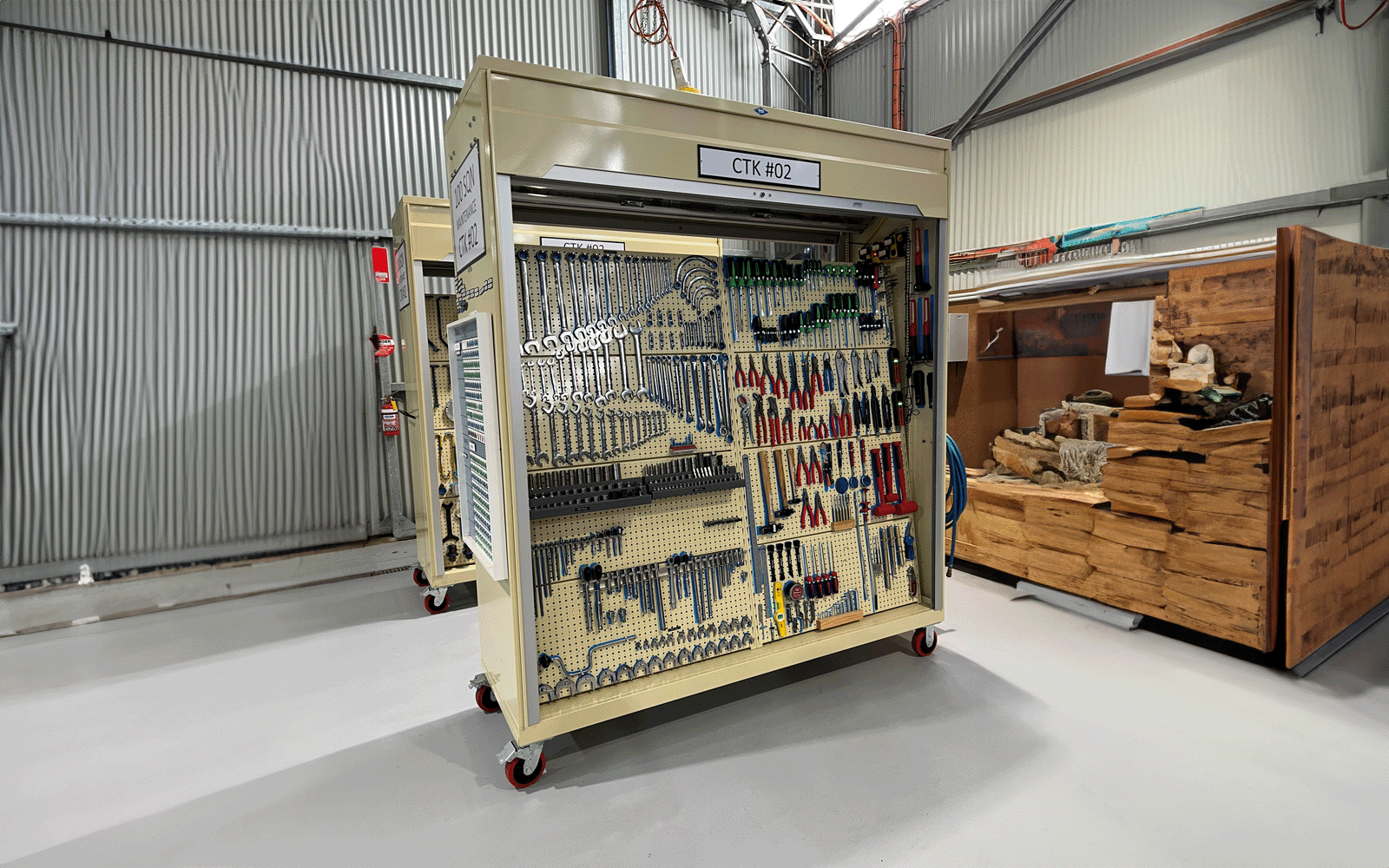

BAC Systems Mobile Workstation

BAC Systems BAC 77 Series - Flat Hose Drawer

Even if you safely avoid the first two hazards, a third lies in wait – the storeperson. Having to wait for a common, day-to-day component to be retrieved by the person behind the counter is a fast way to pull on the reigns of productivity. Who’s to say that a conversation won’t be lying in wait, just to add to the time spent getting the part?

The consulting team at BAC Systems recognise the place for a centralised store, with stringent inventory control and accountability but, it is true to say, there are many instances where productivity can be greatly increased, without any real loss of inventory control, through the establishment of satellite parts and consumable storage solutions.

In the case of engineering and electrical parts and consumables, it would be fair to plan a storage system around those parts that are used at least once a fortnight, and to place this storage system at Point-of-Use. Point-of-Use may refer to a particular work-bay, or, a machine, where the parts will always be required, and, Point-of-Use may also refer to that place where parts are collected in order to be taken out to a job, such as in a maintenance workshop.

BAC Systems developed its BAC High-Density Drawer Storage Cabinets just for these scenarios. With capacities between 50 and 700 parts, a BAC Cabinet is a modular approach to squeezing many parts into a tiny footprint with absolutely no loss of order, and, with better vision of parts and labels. BAC Drawers can be selected based upon their height, and the internal partitioning of the drawer can be chosen, and easily adjusted, to suit the parts being stored. With this three-dimensional configuration, space wastage can be avoided and, thus, the storage footprint can be reduced dramatically. As each location can be labelled, a unique location can be created for each part, and multiple parts never need to be stored in the same location. Additionally, when you pull a drawer open (which takes barely a second to do), you can instantly see the complete contents of the drawer, which stock needs replenishing, and where available storage locations are. Obviously, this saves a lot of time, when compared to pulling individual boxes out from a shelf, when stock taking and identifying parts.

BAC Systems have also looked at the hydraulic hose room, and have come up with similarly useful solutions for the consumables required. Obviously, for the fittings and couplings, the BAC High Density Drawer Storage are the obvious choice, but the lengths of uncut hoses have always presented the logistics problem in hose stores. Now, BAC Systems has recently introduced its hose storage solutions to the market.

BAC Systems has developed a range of drawers designed for storing hoses on their reels. These drawers support between 2-6 reels on a series of rollers, and the hose can be fed out to the nearby saw for cutting. By opening the drawer, it is possible to load the hose reel with a forklift or a crane.

As the hose diameters increase, it is less likely that the hose is to be stored on reels. For the medium diameter hose, stored loosely, a BAC Hose Drawer with turntable would be the number one choice. A hose can be coiled around a turntable, being able to be pulled out as required. The hose is clamped down to avoid tangles and, if too much hose is drawn, it is a simple matter to rotate the turntable to rewind the hose.

For hoses of larger diameters, it is best to keep the hose bundled, and bound with a Velcro cable tie. Instead of storing these on pallet rack or long span, a BAC hose-bundle shelf can be used to stand these bundles in a trough-shaped shelf, with vertical separators, to create easy to access hose locations.

What these different hose storage systems achieve is a means to store lots of hydraulic hose right next to the hose saw. Hoses can be turned around in a short time as forklifts and ladders aren’t required to achieve hose for out-of-the-way shelves in a warehouse. Everything needed for day-to-day hoses is in the hose room and is easy to access. Better still, with the BAC Systems Hose Storage System, you will find that it does not take up too much of your floor space!

To learn of other ways that BAC Systems can increase your productivity through high-density storage, please engage with your local BAC Technical Sales Rep.

To have a BAC Technical Sales Representative visit your hose shop to devise a solution for you, please contact the team at bacsales@bacsystems.com.au